Abstract

Segmentation—assigning pixel-level semantic meaning to visual data—has become the cornerstone of perception-driven systems. Its accuracy directly determines the reliability of robotic manipulation, the safety of industrial automation, and the diagnostic precision of medical imaging. This article examines segmentation’s role across these domains from both a research and engineering perspective. It further outlines how our Computer Vision Services leverage state-of-the-art models, data-centric pipelines, sensor fusion, and deployment optimization to significantly enhance our clients' operational outcomes, establishing a powerful bridge between cutting-edge academic research and real-world impact.

1. Introduction

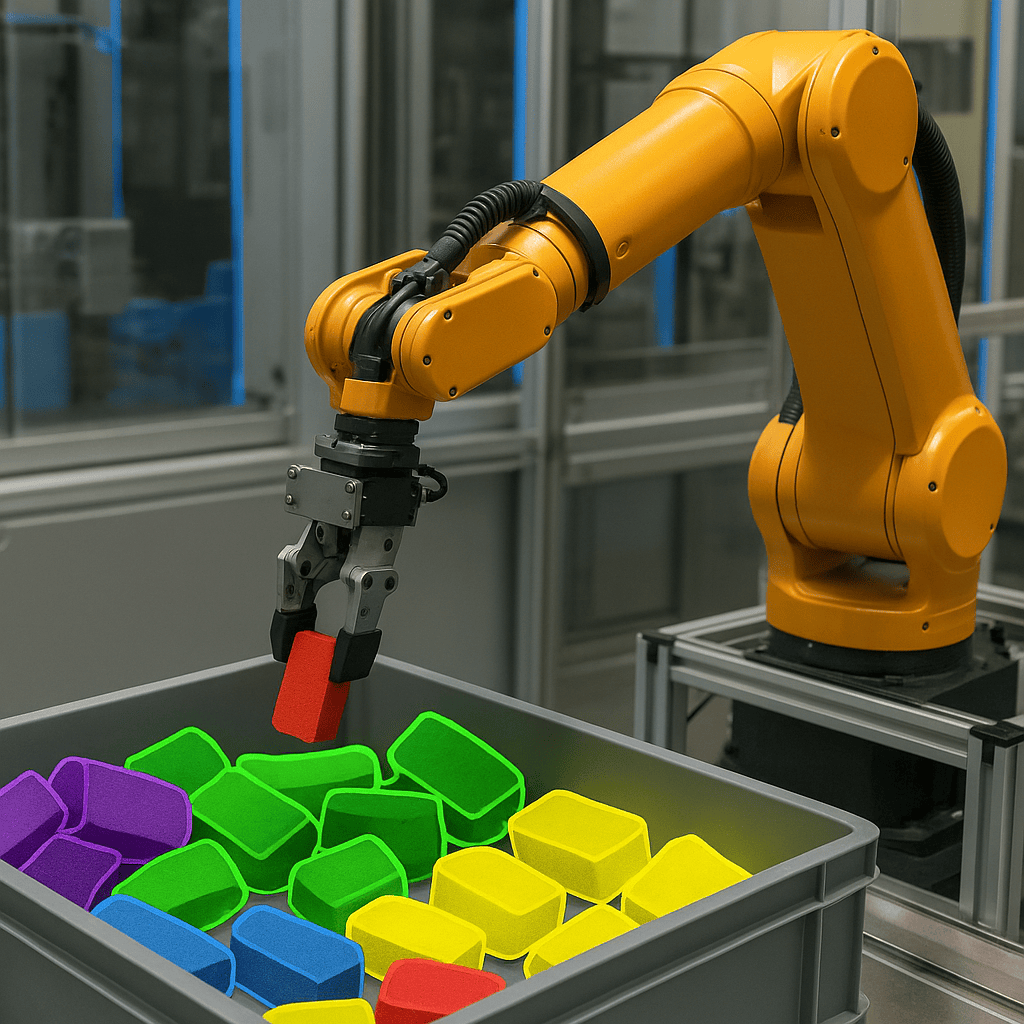

As industries transition toward AI-driven autonomy, the demand for high-fidelity perception systems has intensified. Pixel-level segmentation is no longer a research curiosity—it is a practical necessity. Whether a robot is grasping items from a cluttered bin or a clinician is measuring tumor boundaries, segmentation quality directly influences the accuracy, safety, and reliability of downstream decisions.

At Miracle Eye / Visual Grab Computer Vision Services, our mandate is to transform these complex segmentation challenges into scalable, real-time, production-ready solutions. We build customized CV pipelines that allow our clients to achieve higher throughput, greater reliability, and significantly improved decision confidence.

2. Industrial Robotics: How Segmentation Drives Intelligent Automation

2.1 Precision Manipulation as a Service

For robotic item picking, segmentation accuracy determines the system’s ability to identify object boundaries, compute grasp points, and estimate pose. Our segmentation-driven grasp planning modules help clients:

Reduce grasp failures

Minimize double-picks

Improve 6DoF pose estimation

Achieve stable picking performance across cluttered bins

By integrating segmentation with motion-planning intelligence, we deliver turnkey modules that can be deployed on industrial robots, AMRs, or AGVs.

2.2 Safety and Collision Prevention for Industry 4.0

We enhance client robotic systems through segmentation-powered collision modeling—ensuring safe trajectory generation even in dense, unstructured environments. This reduces mechanical wear, avoids bin collisions, and ensures predictable robot performance.

2.3 Increasing Operational Throughput

Using high-fidelity segmentation, clients experience measurable improvements in cycle time. Our optimized models (ONNX, TensorRT, quantized variants) run in 5–12 ms on edge GPUs, enabling real-time autonomous picking at industrial scale.

3. Medical Imaging: Segmentation as the Backbone of Clinical Accuracy

3.1 Diagnosis Support Modules

Medical image segmentation drives precise measurement and detection of tumors, polyps, organs, and vessels. Through our custom-built medical segmentation frameworks—powered by U-Net, TransUNet, and nnU-Net—we enable healthcare clients to achieve:

Sub-millimeter boundary accuracy

Reliable detection of early-stage anomalies

Reduced inter-observer variability

Enhanced decision-making confidence

These solutions assist radiologists, diagnostic centers, and AI-health startups.

3.2 Treatment Planning and Therapy Optimization

We deliver segmentation models specifically optimized for OAR (Organs at Risk) delineation and tumor localization. Improved segmentation accuracy directly enables safer radiation planning, precise surgical navigation, and more objective monitoring.

3.3 Longitudinal Patient Monitoring Systems

Our segmentation pipelines offer consistent performance across multiple timepoints and modalities, enabling clinicians to track disease progression with scientific rigor rather than algorithmic ambiguity.

4. Enhancing Segmentation Performance: Our CV-as-a-Service Framework

4.1 Custom Architecture Selection & Deployment

We do not deploy generic models. Instead, we select or engineer architectures tailored to each client’s domain:

Industry: Mask R-CNN, YOLOv8-Seg, SAM, DETR-Seg, PointNet++, MinkowskiNet

Medical: U-Net variants, 3D-U-Net, TransUNet, Swin-UNet, nnU-Net

Our team evaluates accuracy–latency trade-offs and deploys the ideal architecture depending on the application—factory floor, operating room, field robotics, or cloud-based analytics.

4.2 Data-Centric Engineering

Segmentation quality is primarily determined by data quality. Our services include:

Industry

Capturing diverse images across lighting, reflections, clutter

Synthetic dataset creation using Omniverse, Blender, Isaac Sim

Annotation optimization pipelines

Healthcare

Multi-expert annotation fusion

Protocol harmonization

Multi-modal dataset integration (CT, MRI, PET, US)

We build or refine datasets to ensure model performance aligns with client-specific deployment conditions.

4.3 Preprocessing & Post-Processing Pipelines

We implement domain-specific enhancements:

Preprocessing

Contrast normalization (CLAHE)

Noise reduction (Gaussian, BM3D)

Depth correction and filtering

Bias-field correction for MRI

Post-Processing

CRF-based mask refinement

Morphological filtering

Shape priors for medical organs

ICP point-cloud refinement for robotics

These modules are delivered as plug-ins integrated into client workflows.

4.4 Multi-Sensor Fusion Solutions

We combine color, depth, thermal, and 3D point cloud data to unlock superior segmentation accuracy.

Industry

RGB + Depth + LiDAR Fusion

3D semantic segmentation

Multi-camera triangulation

Medical

PET-MRI fusion

CT + MRI integrated models

Ultra-high-resolution slice reconstruction

This improves robustness, especially under occlusion or poor imaging conditions.

4.5 Real-Time Optimization for Production Deployment

Our deployment pipeline includes:

TensorRT acceleration

ONNX graph optimization

INT8/FP16 quantization

Pruning & distillation

Edge-device deployment (Jetson Orin, Xavier, Intel Movidius, Coral TPU)

This ensures our clients benefit not only from high accuracy but also from industry-grade inference speeds.

5. Why Our Clients Benefit: The Value Delivered

Industrial Automation Clients Experience:

Fewer grasp failures

Higher throughput

Lower downtime

Improved ROI on robotic systems

Scalability across new SKUs and lighting conditions

Healthcare Clients Experience:

Improved diagnostic consistency

Faster image review workflows

Early disease detection assistance

More accurate surgical and radiation planning

Standardized longitudinal patient analysis

In both domains, segmentation becomes a measurable competitive advantage—one that we deliver end-to-end.

6. Conclusion

Segmentation lies at the heart of perception-driven automation and precision healthcare. Its quality directly influences real-world outcomes—from robotic efficiency to clinical accuracy. Through our Computer Vision as a Service model, we transform cutting-edge segmentation research into practical, deployable, and scalable solutions tailored to client environments.

By merging academic rigor with industrial engineering discipline, we ensure that our clients experience measurable performance gains, reduced operational friction, and a sustained competitive edge.